EMC coating process for shielding

electromagnetic radiation

Latest shielding technology:

The shielding process developed in-house by STB-Abschirmtechnik GmbH is as gentle on materials as it is highly effective.

The new process offers an economical and widely applicable technology for the coating of various carrier materials.

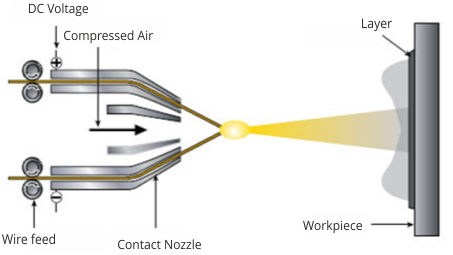

By means of a special, non-chemical and non-thermal pre-treatment, the coating is applied by two melting metal wires, which are under tension and 420 degrees heat, pushed towards each other with compressed air.

The metal melts to oxide and is finely atomized by compressed air at an impact velocity of 100km/s and evenly applied to the substrate.

After the atomization phase, the heated oxide is cooled by the ambient air from (originally 420 degrees) and hits the workpiece at only about 80 degrees.

It is precisely at this point that the important shielding effect now occurs:

Due to the strong cooling of the oxide and the expansion coefficients associated with it, the metal literally becomes entangled with the workpiece and leads to an indissoluble, heterogeneous, fully metallic and corrosion-resistant surface.

On the basis of this newly created layer, a closed, conductive and fully metallic surface is created.

For this reason, it is possible to protect electronic interiors from external radiation influences (Faraday cage) or/and at the same time to prevent radiation through the carrier material to the outside.

EMC – Coated and uncoated surfaces

CNC machining and covering

The simplest way of covering is a full-surface coating of the workpiece, but customer requirements are often individual and filigree. For this reason, we manufacture suitable covering devices for series production in our company.

Areas that are to remain free of a conductive metallic surface are covered accordingly by means of a CNC-manufactured covering device. In this way we obtain a 100% consistent quality and a delimitation accurate to the millimeter.

Depending on the degree of difficulty and sensitivity of the covering device, other covering techniques may also be used. The simplest masking method is the manual masking technique. Silicone pads are also often custom-made and the non-coatable surfaces are protected from metallic coating and kept clean.