Test results of the metallic coating

Over the years, STB Abschirmtechnik GmbH has constantly developed its metallic coating process and is now at the forefront of technological progress.

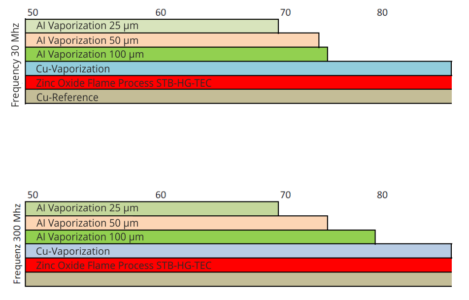

The Frauenhofer Institut für Schicht- und Oberflächentechnik (Fraunhofer Institute for Surface Engineering and Thin Films) has conducted a series of tests comparing different shielding processes on the same substrates.

For this purpose, in this case a zinc coating on various plastics was examined with regard to its adhesive strength, abrasion resistance, layer thickness as well as electrical conductivity.

Both in the high-frequency range (HF) and in the low-frequency range (LF), the shielding process of STB Abschirmtechnik GmbH with its surface technology performs excellently in terms of transmission attenuation values!

For this purpose, test methods specially adapted to the specific properties of the metallic coating were set up:

- Adhesion strength – tensile tester

- Abrasion resistance – scratch tester and abrasion tester

- Coating thickness – special radiators and clipping curves

- Electrical properties – Measuring stand for determination of DC conductivity in climatic cabinet

- Long-term stability – Climatic-humidity alternating conditions

- Shielding effect

Certificate

Radar shield attenuation

(Click to enlarge)

Certificate

EMC shielding attenuation

(Click to enlarge)

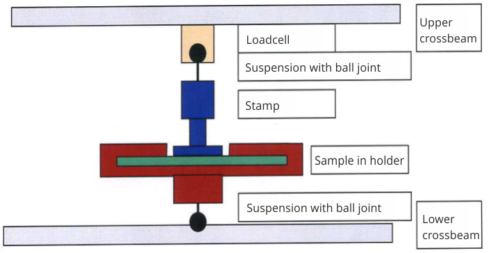

Adhesion testing:

Tested, measured and passed:

By means of a so-called tensile testing machine (Frank81816), the adhesion was tested in the face pull-off method according to DING 582. The result is astonishing.

The values were clearly below those of galvanic processes, but with up to 20 N/mm², the tests partly led to the breaking of the substrate material itself (e.g. with some PE samples ) rather than to the detachment of the zinc layer!

| Adhesion values

Modified polyphenol oxide |

in kg/cm²

24 |

Abrasion resistance testing

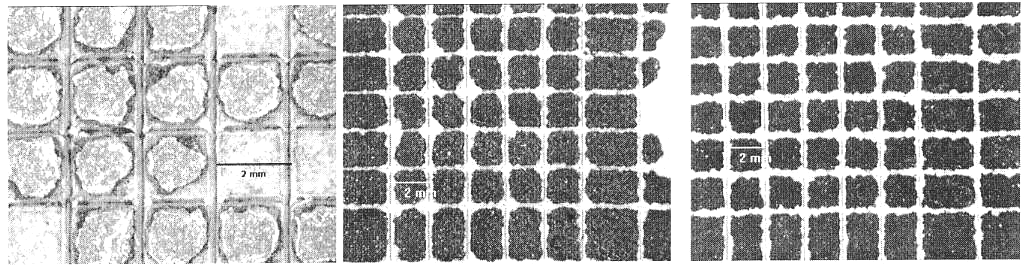

Coating thickness: The statistical design of experiments (SVP) method was used to determine optimum coating properties, identifying the main influencing variables and optimizing their settings. The coating thickness was determined by cross-sectioning. It was found that the roughness of the surface results in a minimal variation of the coating thickness. A coating thickness of 110µm – 120 µm was specified. By using a special post-processing method, we were able to almost compensate for the surface layer thickness difference. (Picture with post-radiation GLAS).

The long-term stability of the coating properties (adhesion and shielding effect) was tested in a climatic chamber under alternating climate-humidity conditions.

Adhesion strength:

The standardized cross-cutting process clearly shows that the adhesion properties of the new metallic surface are ensured even under strong mechanical impact.

Compared with currently known metallic coating processes, the adhesive strength of this surface is often many times greater.