Plastic Metalliziation

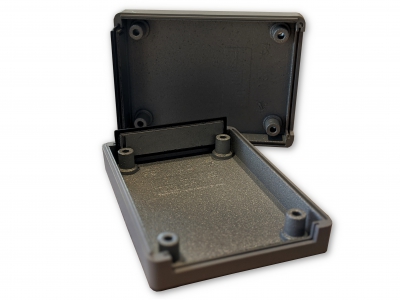

One of the specialties of STB Abschirmtechnik GmbH is the metallization of plastic. The aim of the metallic coating is mainly the EMC protection.

The metallization of various carrier materials is on the one hand to protect the own product from electromagnetic radiation and on the other hand to protect other electronic devices so that they can be operated without interference and damage.

Compared to known metallization processes, the carrier material is neither chemically nor thermally affected during the manufacturing process. Instead, the new, hot-applied, metallic surface forms a kind of protective layer against thermal, mechanical and even chemical influences in the future application process.

The STB Abschirmtechnik GmbH process LINJK!!! can be used to coat various plastics (thermoplastics thermosets, elastomers), carbon, metal, paper, wood, fleece, cork, etc.

Services Metallization of plastic

STB Abschirmtechnik GmbH has specialized in being a service provider for metallic coating for individual customer products. Here LINK!!! you can get more detailed information about the range of services.

Advantages of the coating process

The process of STB Abschirmtechnik GmbH offers numerous advantages. No other metallic coating process combines so many positive and necessary properties when it comes to effective shielding of electromagnetic radiation.

- Extremely good adhesion

- Almost any carrier material can be metallically coated

- Excellent shielding attenuation properties of electromagnetic radiation

- from 30 to 1000 MHz up to 99.999999 % field attenuation

- from 5850 MHz to 8200 MHz up to 99.5 % field attenuation

- Strong protection against atmospheric agents (UV rays, weathering, corrosion and mechanical stress)

- Very high long-term durability (salt spray test – ASTM B117, DIN EN ISO 9227)

- ROHS compliant

- IP 65 suitable

- Solderable surface

- No chemical or thermal degradation of the carrier material

- Cost-effective shielding process

- Layer thicknesses of 20μ – 150μ possible

- CE-compliant (Not harmful to health and can be incorporated into electronic components without hesitation)

- Increased thermal load capacity of the carrier material (due to uniform heat distribution)

- Harmless to health (Suitable for medical industrial applications)

- Ecologically degradable and harmless (Environmentally friendly)

- Recyclable

- Maximizes further processing possibilities (galvanization, pulverization)

Even more information about the process can be found here LINK!!!.

Become a customer now

If you are now interested in our range of services, let’s get talking today! Call us at 05763 9448471 or send an e-mail to info@stb-abschirmtechnik.de!